Description

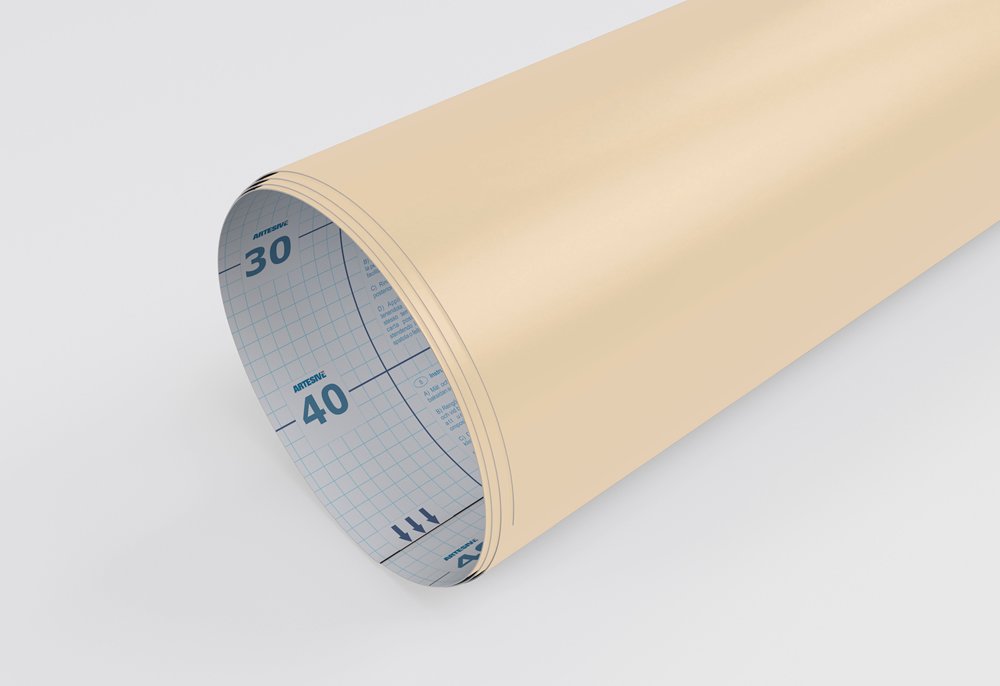

Scegli il tuo rotolo di pellicola

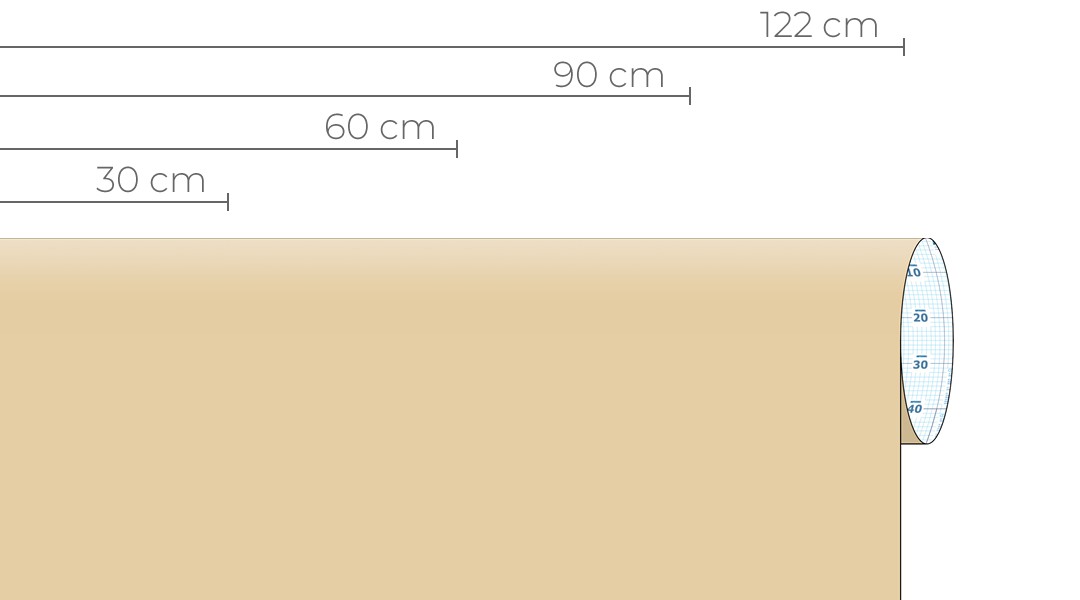

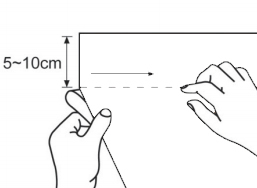

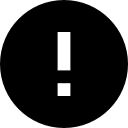

Scegli la larghezza e decidi tu quella ottimale per minimizzare gli sprechi e facilitare l’applicazione. Puoi scegliere tra i vari rotoli pre-tagliati o il rotolo su misura indicando nel campo della quantità i metri esatti di cui hai bisogno. Questo modello è disponibile con quattro larghezze differenti. 30 cm, 60 cm, 90 cm e 122 cm.

Serie Plain Matt

La serie Plain di Artesive rappresenta tutti i modelli a tinta unita. Questo rivestimento adesivo realizzato in PVC offre delle caratteristiche molto particolari, perfetto da utilizzare per rivestire superfici come legno, materiali plastici, metallo e superfici liscie come cartongesso o MDF. La sua superficie delle pellicole a tinta unita sono liscie, senza venature. La versione opaca ha un effetto leggermente poroso al tatto

Qualità e Facilità di utilizzo

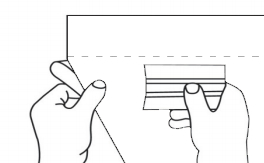

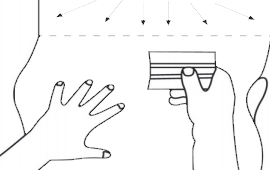

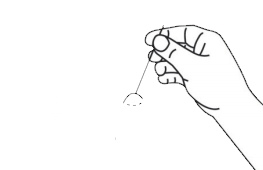

Come tutte le pellicole Artesive, anche quelle della serie Plain sono comformabili, per cui scaldandole si possono modellare e applicare facilmente anche in punti difficili come bordi o spigoli. L’adesivo utilizzato non fa presa subito al 100%, ma permette di poter rimuovere la pellicola per essere riposizionata in caso di errori.

Consultate il diagramma sottostante alcune delle performance normalmente richieste da un rivestimento adesivo per vetri. In una scala da 0 a 100 dove 100 è il punteggio massimo, potrete capire quale modello si presta al vostro utilizzo.

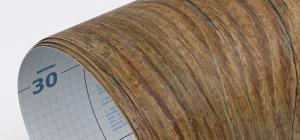

Wood Effect Vinyl Films

Wood Effect Vinyl Films

Stone Effect Vinyl Films

Stone Effect Vinyl Films

Solid Colours Vinyl Films

Solid Colours Vinyl Films

Window Films

Window Films

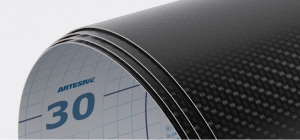

Modern Vinyl Films

Modern Vinyl Films

Specials Films

Specials Films