Description

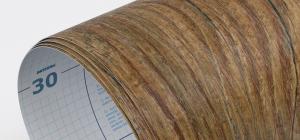

Matt Natural Cedar

The Natural Cedar model texture has a neutral color, ranging from straw yellow to very intense hazelnut veins. The embossing is high and gives a feeling of “rough” finish even to the touch. Perfect for those looking for a fresh and current color, ideal for modern and refined environments. Matte finish, it has the veins in a vertical direction with respect to the length of the coil.

Choose your roll of film

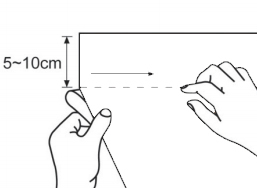

Choose the width and decide the optimal one to minimize waste and facilitate application. You can choose between the various pre-cut rolls or the custom-made roll by indicating in the quantity field the exact meters you need. This model is available in four different widths. 30 cm, 60 cm, 90 cm and 122 cm.

Wood Series

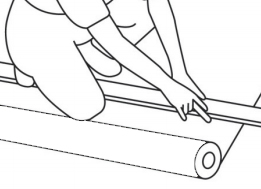

Artesive Wood series represents the perfect combination of materials, design and application performance. This adhesive coating made of PVC offers very special characteristics, perfect to use for coating surfaces such as wood, plastic materials, metal and smooth surfaces such as plasterboard or MDF. Its high thickness surface allows an excellent sensation to the touch as well as to the sight. The grain is felt to the touch and to the eye it looks quite similar to natural wood.

Quality and Ease of Use

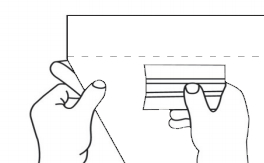

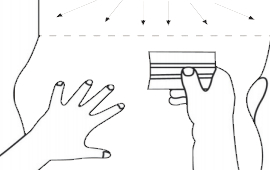

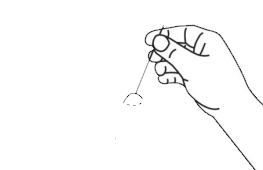

Like all Artesive films, even those of the Wood series are conformable, so by heating them they can be modeled and applied easily even in difficult points such as edges or corners. The adhesive used does not set 100% immediately, but allows the film to be removed to be repositioned in case of errors. The patterns and textures of the Artesive Wood series are in line with the furnishing trends of the moment.

See the diagram below for some of the performance normally required by an adhesive glass coating. On a scale of 0 to 100 where 100 is the maximum score, you can understand which model is suitable for your use.

Wood Effect Vinyl Films

Wood Effect Vinyl Films

Stone Effect Vinyl Films

Stone Effect Vinyl Films

Solid Colours Vinyl Films

Solid Colours Vinyl Films

Window Films

Window Films

Modern Vinyl Films

Modern Vinyl Films

Specials Films

Specials Films